Everyone is buzzing with news about the latest AI breakthroughs, and we at Setronica believe in moving beyond the headlines…

Info Setronica | May 7th, 2025

The world is facing a growing challenge in managing plastic waste, with millions of tons produced annually and only a fraction effectively recycled. As environmental concerns mount, many companies turn to AI to optimize recycling processes.

Their initiatives demonstrate how technology can transform sustainability efforts while providing valuable data to improve future packaging designs and meet regulatory requirements.

So let’s see what they do.

Even with more people caring about recycling, we still don’t recycle enough. Sorting is confusing, and contaminated materials cause problems. The biggest issue? No one knows what really happens to packaging after we throw it away.

This lack of information makes it hard for brands to design better packaging. Companies can’t tell if their environmental efforts actually work because they only have guesses, not real numbers.

Shoppers now want proof that packaging is truly eco-friendly. They want to know their recycling efforts matter and aren’t wasted.

Against this backdrop, technological innovation offers promising solutions. AI-driven systems can provide the missing link in tracking, verification, and optimization of recycling processes. This helps them meet both what customers want and what regulations require.

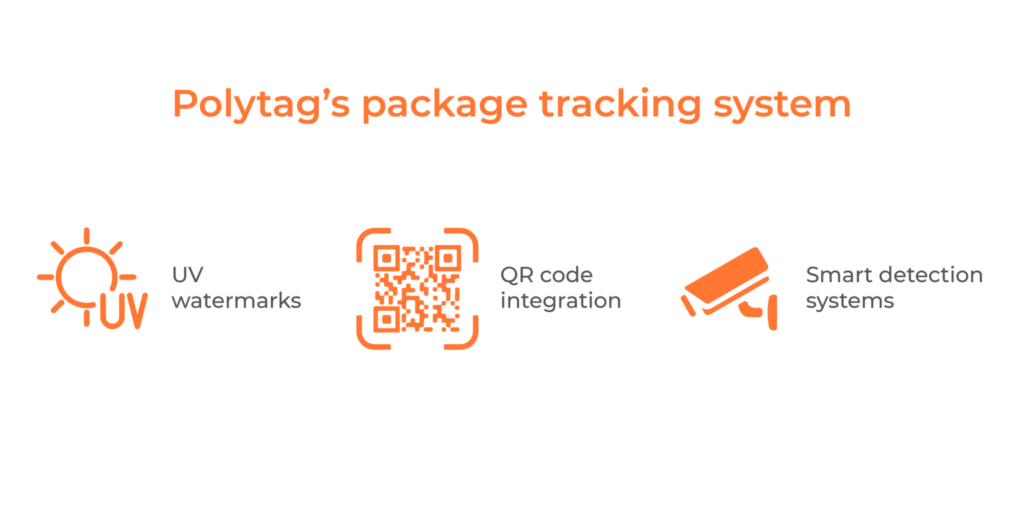

Polytag makes tools that help brands follow their packaging from store to recycling bin and beyond. Their main goal is to show exactly what happens to packaging after use, replacing guesses with real data about how much actually gets recycled.

The core of Polytag’s technology suite includes several components:

Thanks to this, brands can see what happens to their packaging in real time. When packages with Polytag’s hidden marks go through recycling centers with their scanners, the system counts them. This gives brands exact numbers about which products are actually being recycled, down to specific item types.

Aldi is a major discount supermarket chain that operates more than 12,000 stores in 18 countries around the world.

A cornerstone of Aldi’s approach is the use of Polytag’s UV tags across its product range. These hidden marks help Aldi follow where packaging goes after customers use it. When these marked packages arrive at Aldi’s recycling center, special scanners spot the invisible tags. This lets Aldi see exactly which items make it through the recycling process. Instead of guessing how much gets recycled, Aldi now knows the real numbers.

Aldi also uses another tool called eco2Veritas, made by Greenback Recycling Technologies. This AI system tracks the soft plastic bags and wrappers that customers drop off in bins at Aldi stores. The system:

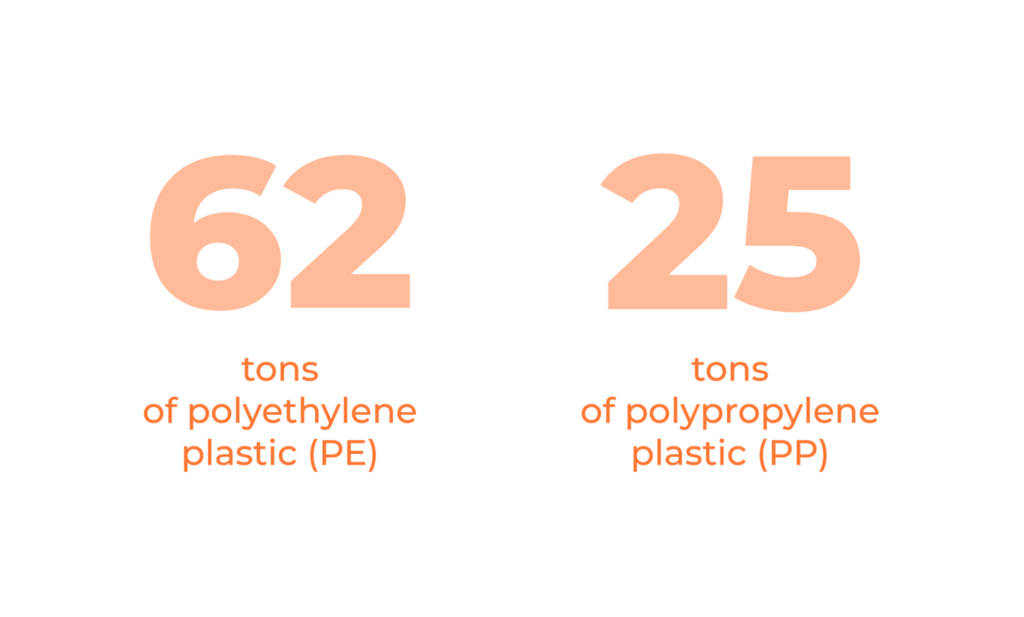

These new tracking tools are already showing real results. In February 2024, Aldi got its first official report showing they recycled:

This plastic came from collections in 2023, and Aldi expects to recycle even more in coming months.

Each year, Aldi collects about 300 tons of soft plastic that customers drop off at store bins. Material from Aldi’s front-of-store collection points is taken to plastics recycler Jayplas, who sorts it into PE and PP. They turn the PE plastic into garbage bags and the PP plastic into storage boxes and trays.

Müller is a German-based company that produces a wide variety of dairy products including milk, yogurt, and other dairy items

The company works with a group called RECOUP on their “Bottle to Bottle” project. They put invisible UV tags on their milk and yogurt containers. These tags let them track where their bottles go during recycling. This collaboration with Polytag provides the company with valuable insights and data about plastic packaging, informing strategic decision-making and shaping responses to recycling policy in the UK.

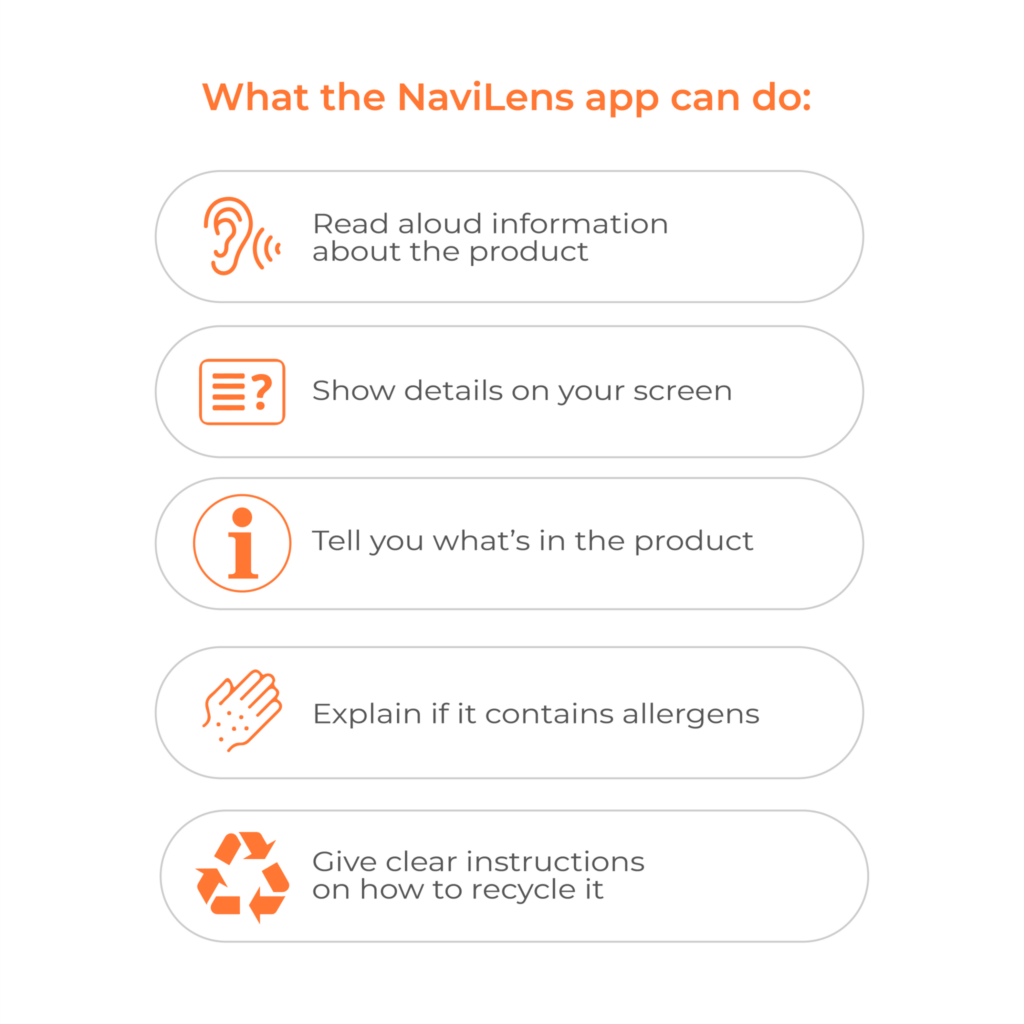

Complementing its tracking capabilities, Müller has adopted NaviLens QR code technology across its product range. These codes do two things at once:

These aren’t like regular QR codes. Your phone can scan NaviLens codes from much farther away – up to 12 times the distance of normal QR codes. You can also scan them from wide angles up to 160 degrees, so you don’t need to hold your phone directly in front of them. This makes them much easier for everyone to use.

When you scan these codes with the NaviLens app, your phone buzzes and makes sounds to help you find and point at the code.

This helps everyone, including people with sight problems, know exactly how to recycle the packaging correctly.

Müller added these special codes as part of updating their packaging and brand look. This fits with their bigger Sustainability Action Plan that aims to make communities stronger and more inclusive.

This new code technology helps people with vision problems deal with challenges that most of us don’t even think about. By using NaviLens and telling people about it in our upcoming ads, we want to make our products easier for everyone to use while also meeting our company goals

Richard Williams, the CEO of Müller Yogurt & Desserts

These new AI recycling tools are just the start of a big change in how companies handle sustainability. Here’s what’s coming next:

Polytag plans to put their scanners in more recycling centers across the UK. As more centers get these AI scanners, we’ll learn much more about what happens to packaging from many different brands.

More companies will likely start using the same tracking systems. When everyone uses similar invisible tags and tracking methods, it becomes easier to share information between stores, recycling companies, and government regulators.

Cities are also getting smarter about trash collection. Many are adding sensors and AI to their garbage trucks and processing centers. In the future, these city systems could connect with brand tracking systems. This would let us follow packaging from when someone throws it away until it becomes something new.

Investing in AI recycling tools makes good business sense. Companies like Aldi and Müller are already seeing real benefits:

The real power comes from working together. As more companies adopt these technologies, they can share costs, create standard ways to track packaging, and learn from each other’s successes.

What started with invisible tags and smart scanners is growing into something much bigger. These AI tools are changing recycling from a system based on guesses to one based on facts. For the first time, we can follow packaging from store shelf to recycling bin to new product.

The future of recycling isn’t just about recycling more – it’s about recycling smarter. With AI tracking every step, brands can make truly sustainable choices, consumers can see the real impact of their recycling efforts. As a result, we all move closer to a circular economy where less goes to waste.

Contact us today to discuss your project and see how we can help bring your vision to life. To learn about our team and expertise, visit our ‘About Us‘ webpage.

Everyone is buzzing with news about the latest AI breakthroughs, and we at Setronica believe in moving beyond the headlines…

An accrual report helps businesses and investors understand the company’s true financial position.

Accurate segmentation of bone structures is crucial for diagnosing fractures, planning surgeries, and monitoring the progression of diseases like osteoporosis.

Accurate segmentation of bone structures is crucial for diagnosing fractures, planning surgeries, and monitoring the progression of diseases like osteoporosis.

About a month ago, we launched our very own remote hackathon. Any Setronica developer regardless of their experience, position, or…

Setronica is a software engineering company that provides a wide range of services, from software products to core business applications. We offer consulting, development, testing, infrastructure support, and cloud management services to enterprises. We apply the knowledge, skills, and Agile methodology of project management to integrate software development and business objectives effectively and efficiently.

contact@setronica.com

+1 929 260 3113

Slovenia:

Kolodvorska 7, 1000 Ljubljana

USA:

211 E 7th St, Austin, TX 78701

© Copyright 2024 Setronica. All Rights Reserved.